Professional dive watches overwhelmingly feature sapphire crystal (typically synthetic sapphire) as their watch glass material. This choice isn't just about luxury; it's driven by critical performance advantages essential for the demanding underwater environment:

Exceptional Hardness & Scratch Resistance (Mohs 9):

Sapphire crystal ranks 9 on the Mohs hardness scale, second only to diamond (10). This makes it one of the hardest transparent materials on Earth.

Underwater, divers' wrists inevitably contact rocks, coral reefs, shipwrecks, dive gear, and boat hulls. Mineral glass or plastic crystals would easily scratch, impairing crucial legibility. Sapphire crystal resists virtually all incidental scrapes, keeping the watch face pristine and readable for years – a vital safety feature for divers monitoring time and depth.

Superior Pressure Resistance:

Dive watches must withstand immense water pressure, increasing dramatically with depth.

Sapphire's dense, robust crystal structure offers extremely high compressive strength and rigidity. It reliably withstands the massive pressure exerted on the watch crystal during deep dives (300m, 600m, or deeper) without deforming or cracking.

Essential Foundation for Waterproof Seals:

Water resistance is paramount for dive watches, and the crystal is a critical sealing point.

Sapphire's high rigidity and dimensional stability prevent flexing. This ensures a reliable, long-lasting seal with the case's gaskets (usually rubber O-rings), effectively preventing water ingress – the core requirement for any dive watch.

Excellent Optical Clarity & Environmental Resilience:

Sapphire crystal boasts high light transmission (approx. 92%), equal to or better than standard glass. This guarantees clear readability of the dial even in low-light underwater conditions.

It's highly resistant to UV rays, temperature extremes (cold water/warm water), saltwater, and chemicals (like chlorine), preventing yellowing, fogging, or degradation over time.

Unmatched Durability & Long-Term Value:

Combining scratch resistance, pressure tolerance, and corrosion resistance, sapphire crystal is exceptionally durable. It's designed to last the lifetime of the watch (barring extreme impact damage), eliminating the need for replacements.

This durability protects the investment in a professional dive tool watch, ensuring lasting reliability and value.

Comparing Dive Watch Crystal Materials

Mineral Glass:

Hardness: Lower (Mohs 5-6) - Scratches easily.

Pressure: Moderate impact resistance, but less deep-pressure capability than sapphire.

Best For: Everyday watches or entry-level dive watches due to lower cost.

Acrylic / Hesalite (Plastic):

Hardness: Very Low (Mohs 3-4) - Scratches extremely easily.

Pressure: Good shatter resistance (may dent or pop out under impact).

Best For: Vintage-style watches; requires frequent polishing; optics degrade; rarely used in modern professional divers.

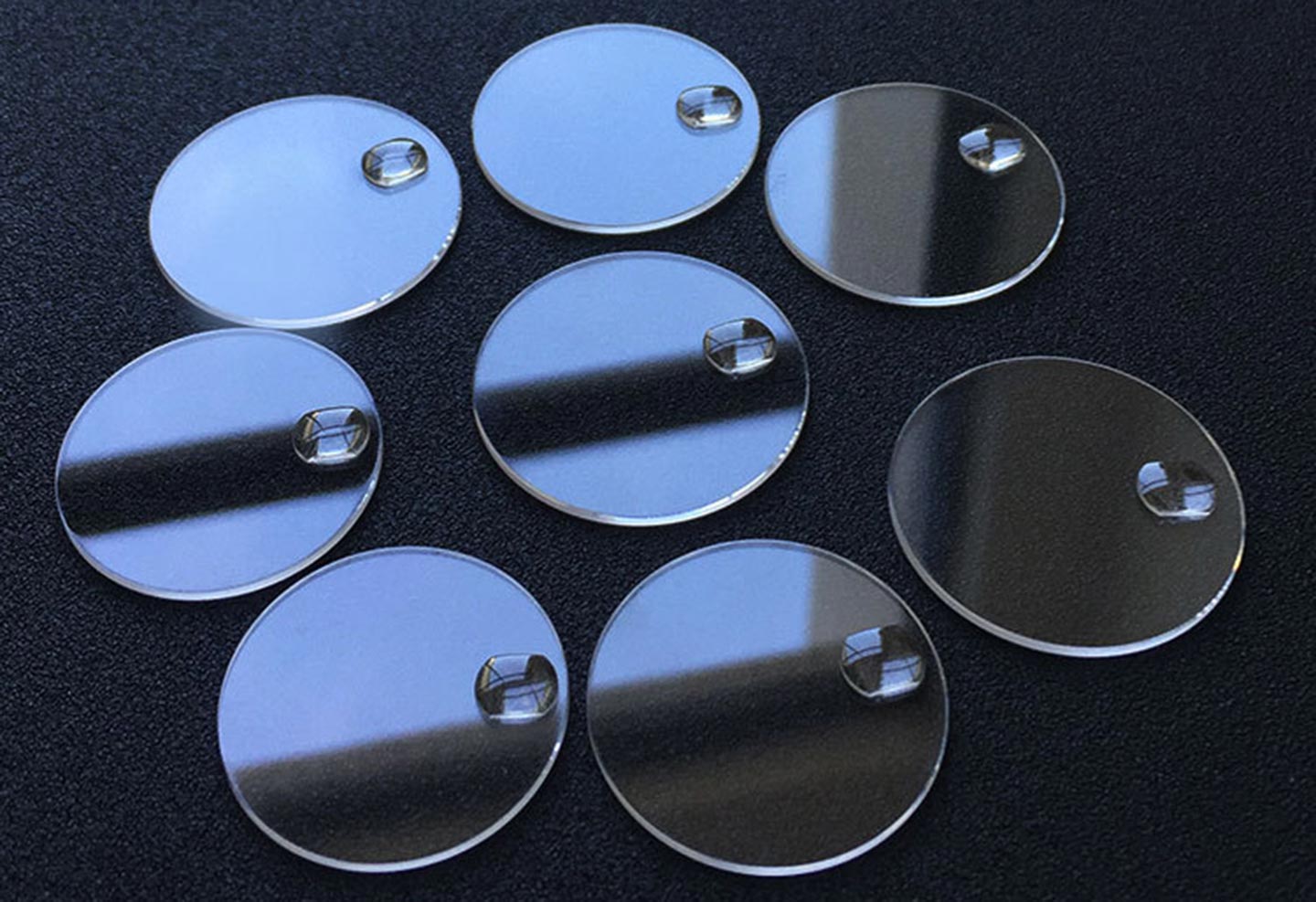

Synthetic Sapphire Crystal:

Hardness: Exceptional (Mohs 9) - Highly scratch-resistant.

Pressure: Excellent - Withstands extreme depths.

Best For: Professional and premium dive watches where reliability, clarity, and longevity are critical. (This is the material discussed above - lab-created for purity and consistency).

For a timepiece that must deliver absolute reliability, safety-critical legibility, and resilience in the harsh underwater world, sapphire crystal is the near-perfect choice. It provides the essential scratch resistance, extreme pressure tolerance, stable sealing surface, optical clarity, and long-term durability demanded by serious diving. While it represents a higher investment than other materials, its unparalleled performance makes synthetic sapphire crystal the undisputed standard for professional-grade dive watches. When your safety underwater depends on clear, accurate timekeeping, sapphire crystal delivers the ultimate protection.

#customdivewatch #divingwatchmanufacturer #odmwatch #oemwatch #watchmanufacturer

Home

Home Gezfeel

Gezfeel Jul 08 2025

Jul 08 2025

Address: Room 405, Building A, Qianhai Zhichuang Technology Industrial Park, No.60 Nanchang Road, Nanchang Community, Xixiang Street, Baoan District, Shenzhen, China

Address: Room 405, Building A, Qianhai Zhichuang Technology Industrial Park, No.60 Nanchang Road, Nanchang Community, Xixiang Street, Baoan District, Shenzhen, China